-

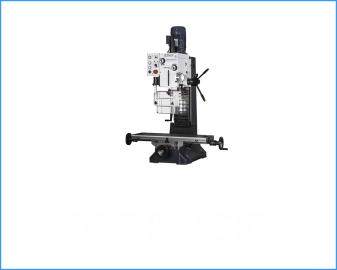

- Electromagnetic clamping plate for fixing the workpiece with automatic demagnetization function

- High-quality spindle with precision taper roller bearings

- Hardened and ground table guideways

- Turcite-B-coated counter-guides for high wear resistance and low friction

- Grinding spindle with high-quality precision bearings

Grinding wheel can be resharpened directly on the machine using a puller device

- Digital position indicator

- Machine base made of stable, torsion-resistant cast iron for maximum rigidity and stability

- Guideways of the longitudinal grinding wheel Lateral and vertical movements are backlash-free and self-centering as V- and flat track design

- Precision ball screws

- Guideways and transport spindle with central lubrication

- All flat tracks are finely scraped and thus guarantee highest precision of all manual movements

- Safety electrical system in 24 V direct voltage

- Largely dimensioned decoupled handwheels in all three axes

- Hydraulic lines according to DIN EN 853

- Grinding accuracy: 0,005 mm

- Corundum grinding wheel grain 46 for all common steels

- Swivelling control panel makes work considerably easier

- Two-channel safety electronics

- Sanding tableSplash guard

- Coolant tank capacity 100 liters

- Digitally controlled automatic vertical feed with servo motor

- Complex hydraulic system with heat exchanger ensures smooth table repositioning even with high table loads

- EMV filter class

- With IE3 motor – consumes considerably less energy and therefore significant cost savings