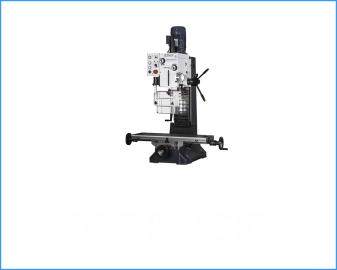

Standard equipment

- 10″ touchscreen NC control G1 for Y and Z axes

- Grinding modes: flat grinding, plunge grinding, cross grinding

- Spindle bearing class P4 from NSK guaranteed concentricity of 0.002 mm Turcite-B coating in the X and Z axes for grinding heavy workpieces

- Backlash-free ball screws in the Y and Z axes

- NC-controlled parallel pull-off and compensation device above the machine table

- Coolant device with magnetic separator

- Partial encapsulation of the work table with monitored door

- Infinitely variable speed of the grinding spindle thanks to an inverter

- Automatic, hydraulic X-axis feed

- Stepless adjustment of the X-axis speed via hydraulic reg elventil

- Automatic, motorized Z-axis feed driven by servo motor

- Adjustment of the end positions in X and Z-axis via joystick

- Automatic, motorized Y-axis feed with servo motor

- electronic handwheel for the Y and Z axes

- automatic central lubrication of all axes/guides

optional special equipment

- NC controlled parallel pulling and compensating device on the grinding head

- Automatic balancing device

- Full encapsulation of the grinding area with two sliding doors

- Additional grinding wheel flanges

- Increased motor performance